The “What is What” of Manufacturing Technology

Manufacturing technology has evolved dramatically, driven by the relentless advancement and integration of new technologies. Historically, manufacturing was characterized by manual labor and simple machines. However, today’s landscape is dominated by automation, digitalization, and complex systems that integrate various cutting-edge technologies.

Emerging technologies have been identified as potential disruptors that could transform the manufacturing sector profoundly. Technologies such as advanced robotics, next-generation genomics, and enhanced energy-storage solutions are paving the way for significant advancements. These technologies promise not only to enhance production capabilities but also to revolutionize the economic and social landscapes. Advanced robotics, for instance, are taking on increasingly complex tasks, improving precision and efficiency in manufacturing processes. Similarly, innovations in genomics are enabling better health diagnostics and treatments, with parallel benefits in agricultural performance through genetic advancements (Disruptive technologies | McKinsey).

Economic Impact

The integration of these technologies is expected to create substantial economic value. A McKinsey report highlights the potential of twelve disruptive technologies to generate an economic impact between $14 trillion and $33 trillion annually by 2025. This projection underscores the transformative potential of these technologies across various sectors.

Strategic Implications for Leaders

For business and policy leaders, the rapid evolution of technology necessitates proactive strategies. Leaders must remain agile, continuously updating organizational strategies to leverage emerging technologies effectively. This includes fostering a workforce capable of managing and advancing these new systems, and potentially redefining business models to capture ne w value pools created by technological advancements.

The integration of cutting-edge technologies in manufacturing is not just enhancing operational efficiencies but is also driving the reconfiguration of the global economic and social order. Leaders must prepare to navigate this complex landscape, ensuring that they harness the benefits while mitigating the risks associated with technological disruptions.

Key Trends in Manufacturing Technology

The manufacturing sector is undergoing rapid transformation, influenced by several key trends that are reshaping the landscape of how products are designed, produced, and delivered.

Industry 4.0 and Automation

The push towards Industry 4.0 marks a significant shift in manufacturing. Smart automation and robotics are at the forefront, significantly enhancing efficiency and reducing human error. Advanced robots are now capable of performing complex tasks with precision, supported by artificial intelligence to make autonomous decisions. This not only speeds up production but also improves safety and quality (Industry 4.0 | McKinsey & Company).

Digitalization and Data Integration

Digitalization is another pillar transforming this industry. By connecting systems and leveraging data, companies can significantly enhance decision-making and operational efficiency. Real-time data collection and analysis allow for quick adjustments to production processes, minimizing downtime and reducing waste. This integration helps manufacturers respond more swiftly to market changes and customer demands, reinforcing the industry’s agility and resilience.

Sustainable Manufacturing

As environmental concerns gain prominence, sustainable manufacturing becomes increasingly crucial. Manufacturers are adopting practices that minimize environmental impact, such as using renewable energy sources and sustainable materials, and optimizing production processes to reduce waste. These practices not only help companies comply with regulations but also appeal to the growing segment of environmentally conscious consumers (Manufacturing Trends – IBM).

Servitization

Manufacturers are moving beyond selling products to offering comprehensive service solutions. This trend, known as servitization, involves providing maintenance, repair, and even upgrades as part of the product offering. This shift helps manufacturers build stronger customer relationships, foster loyalty, and generate stable revenue streams through after-sales services.

Reshoring of Manufacturing

Economic and geopolitical factors are prompting companies to bring operations back to their home countries, a trend known as reshoring. Driven by rising labor costs abroad, supply chain vulnerabilities, and the desire for greater control over quality and intellectual property, reshoring helps companies reduce risks and often leads to cost savings in the long term. This trend is also bolstered by consumer preferences for products made domestically.

These trends highlight the dynamic nature of the sector and underscore the need for companies to adapt swiftly to remain competitive in a rapidly changing global market. Each of these trends not only addresses current challenges but also opens up new opportunities for growth and innovation.

Key Technologies Transforming Manufacturing

The manufacturing industry is being revolutionized by several advanced technologies that not only enhance efficiency but also open new avenues for innovation and customization.

Flexible Automation and Robotics

Flexible automation and robotics are redefining the landscape. Robots are becoming more adaptive and are now integral to manufacturing processes. These robots are equipped with sensors and AI, allowing them to perform tasks with high precision and adapt to different production scenarios without human intervention. This adaptability is crucial for industries where customization and quick changeovers are essential.

Advanced Materials and Additive Manufacturing

The introduction of advanced materials and the expansion of additive manufacturing (3D printing) are significantly impacting efficiency and product customization. These technologies allow manufacturers to create lighter, stronger, and more complex structures that were previously impossible to produce. Moreover, 3D printing is revolutionizing production by reducing waste and enabling on-demand manufacturing, which aligns with the growing trend towards sustainability and efficient use of resources (The future of manufacturing | Deloitte).

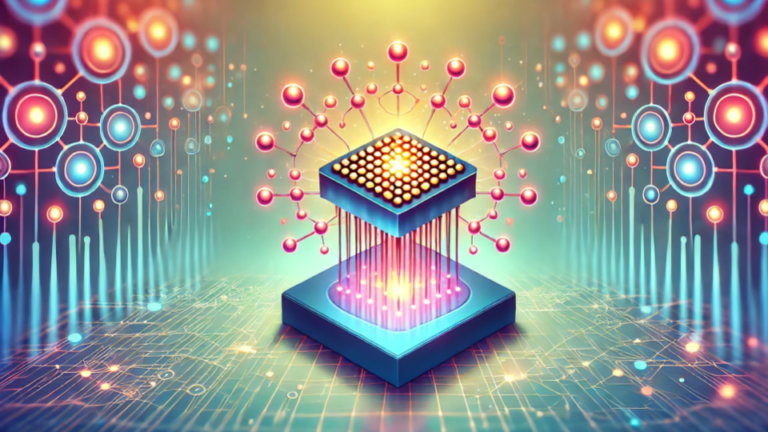

Digital Twins and AI

Digital twins and artificial intelligence are transforming how manufacturers operate and develop products. A digital twin is a virtual model of a physical process, product, or service. This technology enables businesses to analyze data and monitor systems to prevent issues before they occur, plan maintenance more effectively, and use simulations to test changes in a virtual environment before deploying them in the real world. AI complements this by providing insights that drive smarter decision-making and innovation, leading to more efficient and effective operations.

These technologies are not just upgrades to existing systems; they represent a shift towards more intelligent, efficient, and sustainable manufacturing practices. Their adoption is crucial for manufacturers aiming to stay competitive in a rapidly evolving industry.

Innovative Manufacturing Practices

The landscape of manufacturing continues to evolve with innovative practices that are tailored to meet the demands of modern markets and technological advancements.

Microfactories

Microfactories are a game-changing approach, emphasizing small-scale, flexible production units that are highly efficient and tailored for specific products or market needs. These facilities allow for rapid prototyping and customization, making them ideal for industries where innovation and speed are critical. Microfactories also reduce the need for large inventories and can be set up in various locations closer to the end consumers, enhancing supply chain efficiency.

Additive and Subtractive Manufacturing

Combining both additive (3D printing) and subtractive (traditional machining) manufacturing processes allows manufacturers to harness the strengths of both techniques. This hybrid approach enables the production of parts with complex geometries while maintaining the precision and quality of traditional methods. The flexibility of switching between additive and subtractive methods within the same production line streamlines the production process and reduces waste, leading to more sustainable production practices.

Extended Reality (XR)

Extended Reality (XR), which includes augmented reality (AR) and virtual reality (VR), is transforming manufacturing, particularly in training and product development. XR technologies enable manufacturers to create highly immersive training environments for employees, which can accelerate learning and enhance understanding of complex machinery or processes without the risks associated with real-world training. Additionally, in product development, XR allows designers and engineers to visualize and interact with 3D models of products in real time, making it easier to identify potential issues and iterate designs quickly.

These innovative practices are not only enhancing operational efficiency but are also driving greater customization, faster production cycles, and improved quality. As these practices continue to develop, they will play a crucial role in shaping the future.

Economic and Geopolitical Impacts

The advancements in manufacturing technology are reshaping the global economic landscape and shifting geopolitical power balances.

Influence on Global Trade and Economic Stability

Innovations in manufacturing technology significantly impact global trade by enhancing production efficiency and creating new markets. As countries adopt advanced manufacturing technologies, they can enhance their competitive edge, leading to shifts in trade patterns and economic power. For example, nations leading in technologies like robotics and 3D printing are positioning themselves as pivotal players in international markets. This technological leadership can translate into increased exports and greater influence in global trade negotiations (Manufacturing the future | McKinsey).

Geopolitical Power Balances

The distribution of advanced manufacturing capabilities can alter geopolitical dynamics. Countries with robust manufacturing sectors, bolstered by cutting-edge technologies, may experience increased political stability and influence. Conversely, nations lagging in technology adoption might find their strategic positions weakened, potentially leading to economic dependency on technology-leading countries. Such shifts can lead to new alliances and rivalries on the international stage, influencing global stability.

Impact on Labor Markets

The adoption of new manufacturing technologies also has profound implications for labor markets. Automation and robotics, while driving efficiency, can displace traditional manufacturing jobs, leading to job losses in certain sectors. However, these technologies also create new opportunities in high-tech fields, necessitating a workforce skilled in areas like robotics, data analysis, and engineering. This shift demands significant changes in education and workforce training programs to prepare workers for the jobs of tomorrow.

Implications for International Relations

As the technology evolves, it also affects international relations. Countries heavily invested in innovation may seek to protect their intellectual property and technological advancements through stricter trade policies or tariffs. Additionally, the global supply chain’s reshaping, driven by trends like reshoring, impacts diplomatic relationships and trade agreements, as countries reassess their economic strategies and alliances in response to these technological shifts.

These economic and geopolitical impacts highlight the complex interplay between manufacturing technology advancements and broader societal changes. As technology continues to evolve, it will be crucial for policymakers and business leaders to navigate these changes strategically to foster economic growth and maintain global stability.

Future Outlook and Predictions for Manufacturing Technology

The future of manufacturing is poised for dynamic changes driven by technology, with significant implications for the global economy and individual industries. Here’s what we can expect:

Economic Value of Emerging Technologies

Emerging technologies such as generative AI and quantum computing are expected to be substantial economic game changers. Generative AI, building on advancements in machine learning, could potentially add up to $4.4 trillion to the global economy through various applications, from improving productivity to reducing development times for new applications. Similarly, industries like automotive, chemicals, financial services, and life sciences could see an economic impact of up to $1.3 trillion by 2035 due to the adoption of quantum computing.

Industry Transformation

Manufacturing will continue to evolve from its traditional base to include more services and complex global operations. This transformation is largely driven by technological advancements that enable manufacturers to produce more efficiently and cater to increasingly specific market needs. For instance, as manufacturing technologies advance, there is a shift towards more customized production and an increased reliance on services such as R&D and after-sales support, which are becoming integral to manufacturing processes.

Global Manufacturing Landscape

The global manufacturing landscape is expected to experience shifts due to rising consumer classes in developing economies, which will drive new market opportunities. However, this comes with challenges such as volatile resource prices and a shortage of skilled labor, which could complicate operations and require new strategies from manufacturers.

Strategic Priorities

For manufacturers and policymakers, the focus will be on adapting to these changes by developing new capabilities and strategies. This might include investments in education and skills development to ensure the workforce can handle new technologies and processes. Additionally, understanding and planning for the economic impacts of these technologies will be crucial for maintaining competitiveness in a rapidly evolving market (2023 manufacturing industry | Deloitte).

Workforce and Skills Development

The demand for skills related to emerging tech trends is growing faster than the supply, with job postings in fields related to technologies like AI and software development showing significant increases. This highlights the need for continuous learning and adaptation among the workforce to keep pace with technological advancements.

The manufacturing sector’s future will likely be characterized by more integrated global networks, advanced technologies, and a shift towards higher-value, service-driven business models. Companies that can effectively integrate new technologies while also navigating the associated economic and geopolitical challenges will be well-positioned for success in this new era.

The Role of Policy and Education in Manufacturing Technology

Effective policies are essential for supporting the manufacturing sector’s adaptation to new technologies and market conditions. Policymakers must ensure that regulations and initiatives are adaptable to the rapid changes in technology. This includes fostering an environment that encourages innovation and protects intellectual property while also addressing the workforce’s changing needs due to technological advancements. Strategic policy-making should focus on creating a framework that supports technological integration and addresses the economic impacts of these advancements.

Importance of Education and Skills Development

The transformation in manufacturing driven by Industry 4.0 technologies necessitates a parallel evolution in education and skills development. There is a growing need for programs that can quickly adapt to the demands of new technologies, ensuring that the workforce is adequately prepared. This includes both technical skills related to new manufacturing technologies and soft skills that enable workers to adapt to rapidly changing environments. Educational institutions and companies must collaborate to develop curricula and training programs that are aligned with industry needs, focusing on areas like robotics, AI, and digital literacy (4IR capability building | McKinsey).

Capability Building in Companies

Companies must also invest in capability building to harness the full potential of advanced manufacturing technologies. This involves not just training on technical skills but also developing leadership and change management capabilities that are crucial for technology integration. By establishing clear pathways for continuous learning and adapting to new technologies, companies can maintain a competitive edge. Effective capability building requires a clear understanding of business needs, assessing skills gaps, and linking these gaps to strategic business goals. Additionally, adopting a pragmatic approach to digital transformations can help in achieving quicker results and avoiding the pitfalls of overly ambitious projects (Industry 4.0 | McKinsey).

Overall, the integration of policy support and educational advancements with industry needs will be pivotal in driving the future success of the manufacturing sector. As technologies continue to evolve, the synergy between these areas will determine how well the industry adapts and thrives in an increasingly digital and automated world.

Conclusion

The future of manufacturing technology presents both substantial opportunities and significant challenges. As we’ve explored, key trends such as Industry 4.0, digitalization, and sustainable practices are transforming the landscape of manufacturing. The strategic integration of advanced technologies like AI, robotics, and digital twins is enhancing efficiency, enabling customization, and improving decision-making across the sector.

The economic and geopolitical impacts of these technological advances are profound. They are reshaping global trade, altering labor markets, and prompting a need for new strategies in policy and education. To remain competitive and leverage the opportunities presented by these changes, it is crucial for both companies and countries to invest in technological capabilities and foster a skilled workforce prepared for the demands of tomorrow.

In conclusion, staying informed and adaptable is essential in this rapidly evolving environment. Businesses and policymakers must continuously assess and respond to new developments in technology and global market dynamics. By embracing change and fostering innovation, the manufacturing industry can navigate the complexities of the future and drive sustainable growth and competitiveness.

Creative Head – Mrs. Shemi K Kandoth

Content By Dork Company

Art By Dork Company

100 Startups by IIT Madras in 2024: A Landmark Entrepreneurial

IIT Madras, a leader in India’s education and research, embarks on an ambitious journey. In…

Inside Indie Hackers: How a Transparent Community of Founders is

Indie Hackers, established in 2016 by Courtland Allen, is a thriving online community and resource…

Cursor: How 4 MIT Graduates Built the Fastest-Growing AI Startup

Cursor, an AI-powered integrated development environment (IDE), emerged in 2022 as one of the fastest-growing…

Vercel: This Startup Is Quietly Powering the Internet — And

Founded in 2015 by Guillermo Rauch and Naoyuki Kanezawa, Vercel—originally known as Zeit—set out to…

Tella: How This Tiny Team Is Revolutionizing Screen Recording

Tella is a modern screen recording platform built for today’s content creators and video professionals….

CarDekho: How Two IIT Brothers Changed The Way India Bought

CarDekho, a prominent name in the Indian automotive industry, has revolutionized the way people buy,…

Kovai.co: The Startup That Gave ₹14 crore To Its 140

The idea for Kovai.co started when Saravana Kumar, the CEO, was working as a software…

Leave a Reply

You must be logged in to post a comment.