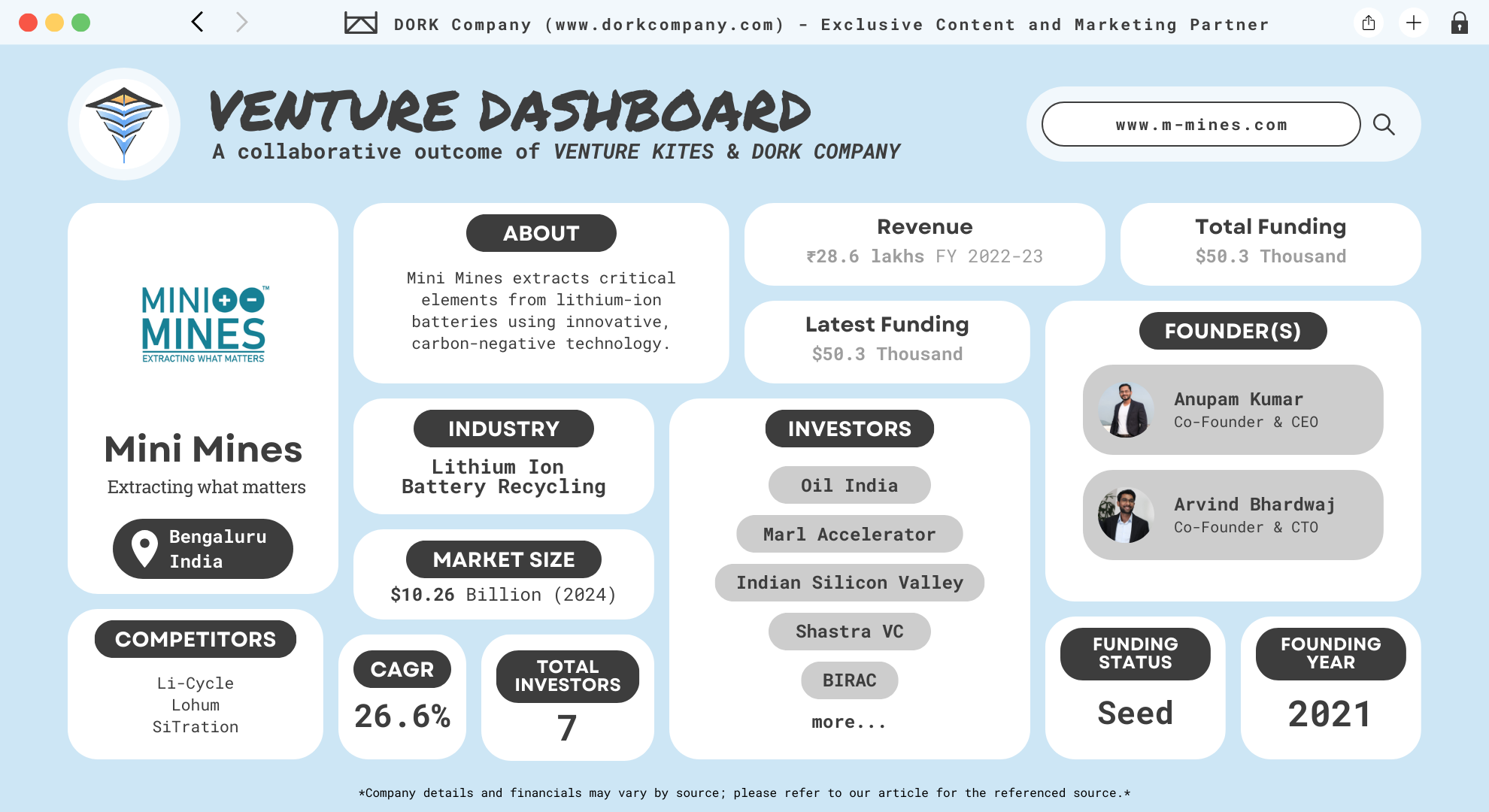

Mini Mines : Recharged and Ready To Power Up the Future of Recycling

This innovative Bengaluru startup, founded in 2021, is revolutionizing the lithium-ion battery recycling industry. With the global shift towards electric vehicles and renewable energy storage, the demand for these batteries is skyrocketing. But what happens when they wear out? With sustainability at its core, Mini Mines is creating efficient, low-cost, and environmentally friendly processes to recycle and extract valuable elements from used lithium-ion batteries. (Mini Mines)

Lithium-ion batteries power everything from our smartphones to electric vehicles. However, as the use of these batteries skyrockets, so does the problem of waste. This process ensures that critical materials like lithium, cobalt, and nickel are recycled and reintroduced into the supply chain without relying on imported raw materials.

Their processes are designed to be carbon-negative, meaning they actively reduce CO2 emissions rather than contributing to them. In just a few short years, Mini Mines has positioned itself as a leader in the clean technology sector. They’ve garnered significant attention for their groundbreaking work, and their journey is just beginning.

Battery-Powered Beginnings: The Sparks Behind Mini Mines

Founded by Anupam Kumar and Arvind Bhardwaj in 2021, Mini Mines is on a mission to reduce the ecological impact of lithium-ion batteries while addressing critical supply chain issues. Both founders bring unique expertise to the table: Kumar, co-founder and CEO is a chemical engineer from the Birla Institute of Technology, began his career at the Bhabha Atomic Research Centre, working on separating valuable elements like uranium, nickel, and cobalt from reactor waste. Bhardwaj, Co-founder and CTO is an expert in lithium-ion battery technologies, previously led the battery division at Log9 Materials, where their shared vision for a greener future took shape. (Anupam Kumar) (Arvind Bhardwaj)

The story of Mini Mines began with a simple realization: EVs and electronics contribute heavily to e-waste. India’s dependency on imported lithium, combined with the environmental cost of traditional mining, posed a significant problem. Kumar and Bhardwaj saw an opportunity to close the loop by extracting valuable metals from spent batteries instead of sourcing them through mining. (Forbes India)

Charged Up: The Booming Business of Lithium-ion Battery Recycling

The lithium-ion battery recycling market is exploding, driven by the surging demand for electric vehicles (EVs) and growing environmental concerns. With the market projected to skyrocket from $10.26 billion in 2024 to $85.69 billion by 2033, at a robust CAGR of 26.6%, recycling lithium-ion batteries has never been more crucial or lucrative (Precedence Research).

Key Drivers

- Rising Demand for Electric Vehicles: The EV boom is a major catalyst, as governments worldwide push for cleaner, greener transportation. EVs depend heavily on lithium-ion batteries, and as these batteries reach their end of life, the need for efficient recycling processes intensifies.

- Government Support and Regulations: Governments are offering incentives and imposing regulations to boost battery recycling. For instance, the U.S. Department of Energy has launched initiatives to recover up to 90% of all consumed lithium-ion batteries, driving innovation in recycling technology.

- Technological Advancements in Recycling Processes: New methods, like hydrometallurgical and pyrometallurgical processes, are making it easier and more cost-effective to extract valuable materials like lithium, cobalt, and nickel from used batteries. This not only supports the circular economy but also reduces dependency on raw material mining.

Market Challenges

However, the market faces significant challenges, including high costs associated with recycling, safety concerns related to battery disposal, and complex regulatory frameworks. Recycling facilities require substantial investment, and managing hazardous chemicals during the process is critical to avoid environmental harm.

Regional Insights

Asia-Pacific leads the charge, thanks to its dominance in battery manufacturing and favorable government policies supporting recycling. North America is rapidly catching up due to strategic partnerships and investments in recycling infrastructure, while Europe is bolstered by strict environmental targets and robust recycling mandates (Fortune Business Insights).

Leading Players

Key players like Umicore, Glencore, and Li-Cycle are pioneering in the industry, developing state-of-the-art recycling facilities and expanding their capabilities through strategic alliances. These companies are at the forefront, ensuring that valuable materials from spent batteries are reintroduced into the supply chain, thereby reducing the ecological footprint of battery disposal (Markets and Markets).

The lithium-ion battery recycling market is on the cusp of significant growth, fueled by technological advancements, supportive policies, and the relentless push toward a sustainable future. As EV adoption continues to soar, so too will the need for efficient, safe, and profitable battery recycling solutions.

Full Circle: Mini Mines’ Mission to Close the Loop

Mission: Driving Sustainable Change

Mini Mines’ mission is to create a cleaner, more sustainable future by revolutionizing how we recycle lithium-ion batteries. The company is committed to extracting and recycling critical elements like lithium, cobalt, and nickel in a way that significantly reduces carbon emissions. They aim to provide 100% regenerative solutions by 2050, aligning with global efforts to combat climate change and resource scarcity. (About)

Vision: A Circular Economy

Mini Mines envisions a world where waste is a thing of the past. They are pioneering efforts to build a circular economy, where resources are reused, and environmental impact is minimized. By developing innovative recycling technologies, Mini Mines seeks to eliminate the need for new raw material extraction, reducing the environmental footprint of industries reliant on lithium-ion batteries.

Problems They Solve: More Than Just Recycling

Mini Mines solves some of the most pressing environmental issues of our time. The company addresses the growing problem of electronic waste, which is expected to surge as the use of electric vehicles and portable electronics continues to rise. By offering a sustainable recycling solution, Mini Mines helps reduce the environmental hazards associated with battery disposal, such as soil and water contamination.

Business Model: Innovation Meets Efficiency

Mini Mines operates on a business model that combines innovation with efficiency. Their proprietary Hybrid Hydro-Metallurgy™ (HHM) process is at the core of this model. This technology allows them to recycle end-of-life batteries and battery manufacturing scrap with minimal environmental impact. The process is designed to be cost-effective, utilizing economies of scale and low-cost raw materials to maximize profitability while minimizing costs.

Mining Magic: The Game-Changing Products of Mini Mines

Mini Mines specializes in extracting and refining critical elements like lithium, cobalt, nickel, and magnesium from used lithium-ion batteries. These materials are then reintroduced into the supply chain, providing battery manufacturers with high-quality, recycled raw materials. (Products)

Comprehensive Recycling Solutions

The company offers a range of services aimed at making battery recycling as seamless and efficient as possible. Their flagship service is the recycling of end-of-life lithium-ion batteries through their proprietary Hybrid Hydro-Metallurgy™ (HHM) process. This process is designed to handle various types of batteries, ensuring maximum recovery of valuable materials. Hydrometallurgy involves using aqueous solutions to extract metals from their ores, while pyrometallurgy uses high temperatures.

Additionally, Mini Mines helps companies meet their Extended Producer Responsibility (EPR) obligations, offering tailored solutions to stay compliant with environmental regulations.

Innovations: A Unique Approach to Recycling

At the heart of Mini Mines’ operations is their innovative Hybrid Hydro-Metallurgy™ process. Unlike traditional recycling methods, which can be costly and environmentally damaging, the HHM process is both cost-effective and sustainable. It’s a closed-loop system designed to maximize resource recovery while minimizing environmental impact.

Features: Sustainability Meets Efficiency

What sets Mini Mines apart from its competitors is its focus on sustainability. Their processes are designed to be carbon-negative, meaning they actively reduce CO2 emissions. The company also prioritizes energy efficiency, using renewable energy sources to power their operations whenever possible.

Mini Mines’ Big Impact in the Cleantech World

Mini Mines has made a substantial impact on the lithium-ion battery recycling market. By introducing their Hybrid Hydro-Metallurgy™ technology, they’ve set new standards for efficiency and sustainability. The innovative efforts of Mini Mines have not gone unnoticed. They have been recognized as one of the top 30 Cleantech Startups of India by the Agence Française de Dévelopement (AFD), Government of France and Ministry of Urban Development, Government of India. (AFD)

They have been backed by institutions like Oil India Limited and the Biotechnology Industry Research Assistance Council (BIRAC), which have provided both financial and strategic support to help scale their operations.

One of their most notable collaborations is with Oil India Limited, a major public sector enterprise. This partnership has provided Mini Mines with the financial backing and resources needed to scale their operations and refine their proprietary Hybrid Hydro-Metallurgy™ (HHM) process.

Money Talks: The Financial Fuel Behind Mini Mines

Mini Mines’ financial journey began with a seed funding round shortly after its inception in 2021. This initial capital injection was crucial for setting up their operations and developing the Hybrid Hydro-Metallurgy™ (HHM) technology. (Tracxn)

The company’s funding milestones include:

- December 2022: Mini Mines received an undisclosed grant as prize money, backed by Oil India, one of their key corporate partners. This funding helped push their research and development forward while refining their proprietary Hybrid Hydro-Metallurgy™.

- October 2022: In their seed round, Mini Mines secured $50.3K, bringing their company valuation to $15.9 million. The funds were provided by the Marl Accelerator, an institution that has been crucial in supporting clean technology startups.

- June 2022: The company also received another undisclosed grant from the Biotechnology Industry Research Assistance Council (BIRAC), aimed at advancing their lithium-ion battery recycling technology.

Mini Mines’ revenue has been growing alongside its operational expansion. In the fiscal year 2022-23, the company reported a revenue of 28.6 lakh INR, up from 0.2 lakh INR in the previous fiscal year. This sharp increase in revenue highlights their successful commercialization efforts, including their first commercial order with UNIDO in early 2023.

From Small Sparks to Big Fires: Why Mini Mines is Just Getting Started

Mini Mines has proven that with the right technology and vision, even the most daunting environmental challenges can be addressed effectively. Their innovative approach to lithium-ion battery recycling is setting new standards in the cleantech industry. As the demand for lithium-ion batteries continues to grow, so does the need for effective recycling solutions.

But what about you? If you’ve got an idea simmering in your mind, now is the time to take action. Whether it’s a sustainable business, an innovative startup, or just a bold idea, the world needs more problem solvers like Mini Mines.

Feeling inspired? Don’t stop here. Check out more articles on Venture Kites for insights into the latest trends, success stories, and expert advice to fuel your entrepreneurial journey.

At a Glance with DORK Company

Dive In with Venture Kites

Lessons From Mini Mines

Prioritize Intellectual Property

Why It Matters: Protecting your intellectual property (IP) ensures that your innovations remain yours and gives you a competitive edge in the market.

Implementation: Invest in securing patents and trademarks for your unique technologies and processes. Continuously innovate to stay ahead of the competition.

How Mini Mines Implements It: Mini Mines has built a strong portfolio of patents around their recycling technology, securing their place as a leader in the industry.

Align with Regulatory Trends

Why It Matters: Staying ahead of regulatory changes allows you to avoid compliance issues and take advantage of new opportunities as they arise.

Implementation: Keep a close eye on industry regulations and adapt your business practices to comply with or exceed these standards.

How Mini Mines Implements It: Mini Mines works closely with government bodies to ensure their processes align with environmental regulations, such as Extended Producer Responsibility (EPR) requirements.

Diversify Revenue Streams

Why It Matters: Relying on a single source of income can be risky. Diversifying revenue streams helps stabilize your business during market fluctuations.

Implementation: Explore different ways to generate income within your industry. This could include expanding your product line or offering complementary services.

How Mini Mines Implements It: Mini Mines generates revenue not just from recycling services but also from selling the recovered materials back into the supply chain.

Embrace Holistic Planning

The Lesson & Why It Matters: Comprehensive planning that anticipates various market scenarios can significantly increase a company’s adaptability and resilience.

Implementation: Companies should develop flexible business strategies that allow for adjustments based on market demand and resource availability.

How Mini Mines Implements It: Mini Mines adopts a dynamic approach in its mining operations, allowing for scalability and responsiveness to market changes.

Foster a Culture of Operational Excellence

The Lesson & Why It Matters: A strong culture of operational excellence can lead to sustained improvements across productivity, safety, and efficiency.

Implementation: Develop a culture that values continuous improvement, supported by training and empowering employees.

How Mini Mines Implements It: By continuously refining their processes and embracing innovative solutions that improve operational outcomes.

Author Details

Creative Head – Mrs. Shemi K Kandoth

Content By Dork Company

Art By Dork Company

Instagram Feed

X (Twitter) Feed

Meet @mminescleantech , from Bengaluru founded by Anupam Kumar & Arvind Bhardwaj transforming lithium-ion battery recycling with carbon-negative tech!

— Venture Kites (@VentureKites) October 15, 2024

Full story @VentureKites:https://t.co/XWUmnwQQb5

Proudly crafted in collaboration with @dorkcompany_ – https://t.co/9nMJIiNnJH pic.twitter.com/pqjXIytklV