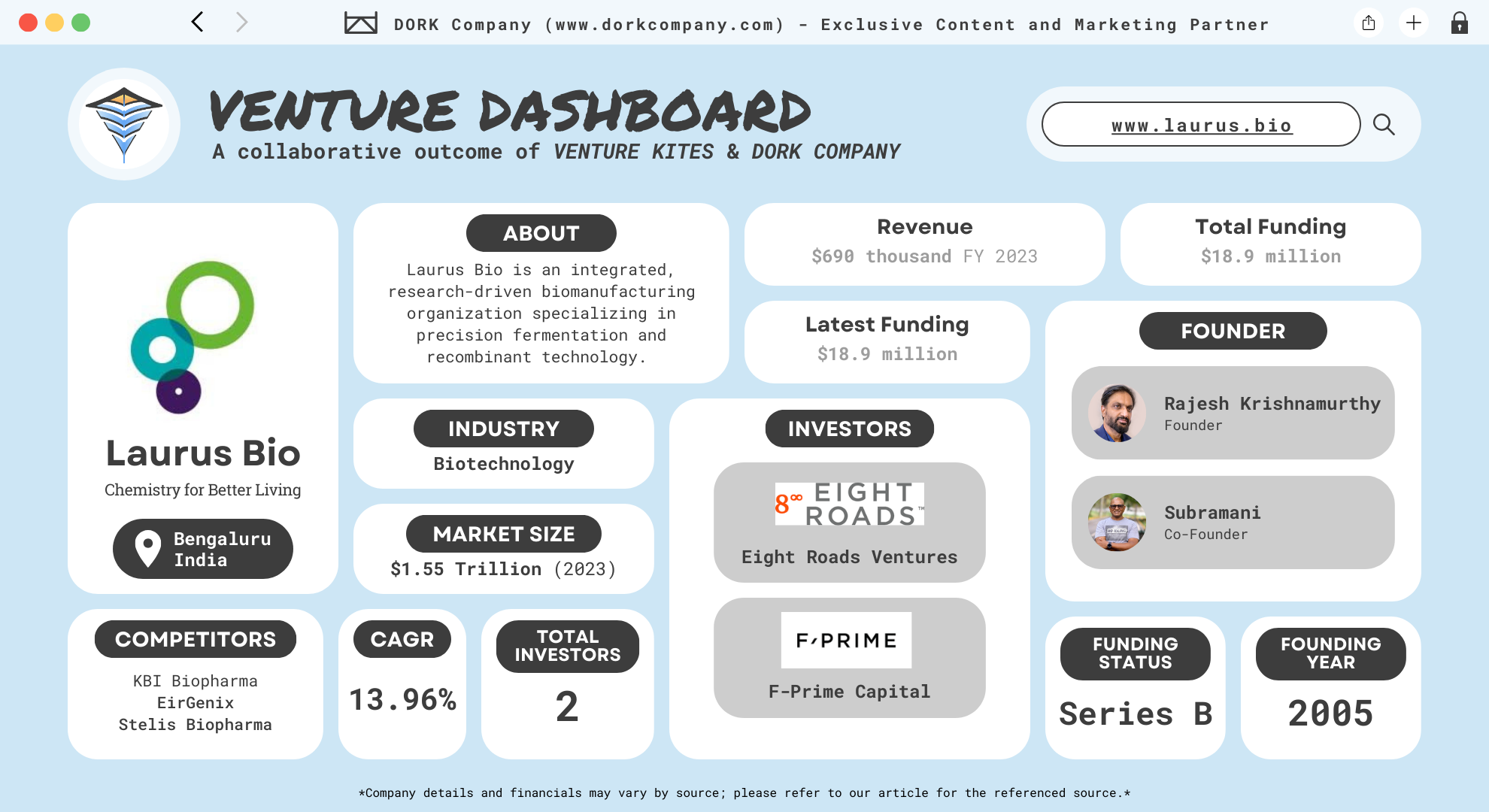

Laurus Bio: Crafting a Future Free of Animal Origins, One Protein at a Time

Laurus Bio, formerly known as Richcore Lifesciences, is a biotechnology company based in Bengaluru, India. Founded in 2005 by Rajesh Krishnamurthy and Subramani Ramachandrappa, the company specializes in precision fermentation and recombinant DNA technology. Their primary focus is on developing and manufacturing animal-origin-free recombinant proteins, growth factors, and cell-culture media supplements. These products are essential for various industries, including biopharmaceuticals, food, health, nutrition, and personal care. (Laurus Bio)

Laurus Bio operates as an integrated research-driven biomanufacturing organization. They engineer microbes to function as “cell factories,” producing novel and sustainable animal-free proteins. This approach aims to replace traditional animal-derived products, promoting safer and more sustainable alternatives in the market.

By harnessing the power of precision fermentation and synthetic biology, Laurus Bio is paving the way for a global shift away from animal-derived products, making medicines, food, and the world safer and more sustainable.Their dedication to replacing animal-derived products with sustainable alternatives positions them as a key player in the biomanufacturing industry.

From Ideas to Microbial Factories: The Founders Who Engineered a Dream

Laurus Bio, originally known as Richcore Lifesciences, was founded in 2005 by Rajesh Krishnamurthy and Subramani Ramachandrappa in Bengaluru, India.

Rajesh Krishnamurthy

With an MBA from ISB’s joint program with the Kellogg and Wharton schools and a Master’s in Environmental Engineering from Texas Tech University, Rajesh honed his skills in leadership, change management, and biotechnology. Before joining Laurus Bio, he gained valuable global business development and strategic sales experience at Maritz in the USA. He now also leads as CEO of Laurus Bio and manages Vivnova Ventures.

Subramani Ramachandrappa

Subramani Ramachandrappa, an engineer with an MBA from the Indian School of Business (ISB), is a serial entrepreneur in the biotech industry. His path began with a Bachelor of Technology in Textile Technology from GSKSJTI, followed by an MBA from ISB. He founded Richcore Lifesciences, which later became Laurus Bio, focusing on animal-origin-free recombinant proteins and enzymes. He also founded Fermbox Bio Inc., a foodtech company in the USA focusing on producing cultivated animal fats without animals. Additionally, he is the managing partner of Vivnova Ventures LLP.

The story of Laurus Bio began with the founders recognizing the urgent need for sustainable and ethical alternatives in biotechnology. They shared a commitment to addressing global challenges in food security, clean technology, and precision fermentation.

A Market Worth Engineering: The Growing Scope of Biotech

The global biotechnology market has experienced significant growth in recent years and is poised for continued expansion. In 2023, the market was valued at approximately USD 1.55 trillion. Projections indicate that it will reach around USD 3.88 trillion by 2030, exhibiting a compound annual growth rate (CAGR) of 13.96% during the forecast period. (Grand View Research)

Several factors contribute to this robust growth. Advancements in genetic engineering, biopharmaceuticals, and bioinformatics have revolutionized healthcare, agriculture, and industrial processes. These innovations have led to the development of personalized medicine, improved crop yields, and sustainable solutions, driving the biotechnology sector forward.

Government support also plays a crucial role in the market’s expansion. Initiatives aimed at modernizing regulatory frameworks, improving approval processes, and enhancing reimbursement policies have created a conducive environment for biotechnology companies to thrive. Additionally, the growing demand for synthetic biology applications has opened new avenues for research and development within the industry.

The precision fermentation segment, a subset of biotechnology, is experiencing particularly rapid growth. In 2023, the global precision fermentation market was valued at approximately USD 2.80 billion. It is projected to grow at a remarkable CAGR of 43.2% from 2024 to 2030, driven by increasing consumer demand for sustainable and eco-friendly products. (Grand View Research)

Mission Possible: Laurus Bio’s Blueprint for a Better Tomorrow

Mission and Vision

Their mission is to engineer microbes as “cell-factories” to produce novel, sustainable, animal-free proteins and growth factors. These products aim to replace animal-derived components in industries such as biopharma, food, health, nutrition, and personal care. The company envisions creating safer, more reliable, and sustainable solutions to address current health challenges.

Problems They Solve

Laurus Bio addresses several critical problems in the biotechnology and pharmaceutical sectors. Traditional reliance on animal-derived products poses risks of contamination and variability, which can compromise product safety and consistency. By developing AOF recombinant proteins and growth factors, Laurus Bio mitigates these risks, ensuring virus-free and consistent quality in biomanufacturing processes. This innovation supports the global shift towards sustainable and ethical production methods, reducing dependence on animal sources and promoting environmental sustainability.

Business Model

Operating as an integrated research-driven biomanufacturing organization, Laurus Bio’s business model encompasses the entire value chain from clone development to large-scale commercial manufacturing. Their expertise in microbial precision fermentation enables them to offer Contract Development and Manufacturing Organization (CDMO) services, providing scalable solutions for clients in various sectors. By leveraging advanced biotechnology, they produce high-quality, animal-free products that meet stringent global standards, including ISO, cGMP, FSSC 22000, Kosher, and Halal certifications.

Protein Perfection: Laurus Bio’s Menu of Marvels

Laurus Bio offers an extensive range of animal-origin-free recombinant proteins and growth factors, playing a pivotal role in biopharmaceuticals, regenerative medicine, cultured meat, and other industries.

Recombinant Human Albumin (10% and 20%)

Laurus Bio produces recombinant human albumin in concentrations of 10% and 20%, expressed in Pichia Pastoris. Albumin, a globular protein with 585 amino acids, is critical in cell culture, diagnostics, and therapeutic applications. It acts as a stabilizer in biologics, maintaining pH balance and oncotic pressure. Its antioxidant and anti-inflammatory properties make it essential for industrial manufacturing and medical device coatings. These properties ensure virus-free and consistent processes across biomanufacturing and research applications.

Recombinant Insulin-Like Growth Factor (IGF1-LR3)

IGF1-LR3, expressed in Escherichia coli, is a long-lasting analogue of human IGF-1 with enhanced mitogenic activity. Comprising 83 amino acids, this protein stimulates cell proliferation, differentiation, and survival. It is widely used in serum-free cell culture media and cultured meat production, promoting growth and regeneration. Its extended half-life and superior bioactivity make it indispensable in cellular applications.

Recombinant Epidermal Growth Factor (EGF-L)

EGF-L is a 106-amino-acid polypeptide, expressed in Escherichia coli, designed for high performance in serum-free media. It binds to EGFR, initiating cell growth, differentiation, and survival through multiple signaling cascades. EGF-L is integral to endothelial and stem cell culture systems and cultured meat production, ensuring consistent performance in applications requiring cell growth modulation.

Recombinant Fibroblast Growth Factor Basic (FGFb)

FGFb, part of the fibroblast growth factor family, consists of 155 amino acids and is expressed in Escherichia coli. It drives proliferation in embryonic and mesenchymal stem cells, aiding tissue regeneration and growth. As a major serum-free media component, it supports diverse applications in cell culture, regenerative medicine, and cultured meat production. FGFb’s high efficacy in growth promotion ensures its relevance across biotechnological applications.

Recombinant Thermolysin

This thermostable metalloproteinase, expressed in Bacillus subtilis, is a 316-amino-acid enzyme with proteolytic activity optimized between 65°C and 85°C and pH 5.0–8.5. Thermolysin catalyzes the hydrolysis of peptide bonds in hydrophobic amino acids. It is used in peptide mapping, protein structural analysis, and tissue dissociation, particularly in regenerative medicine. Its high thermal stability makes it a reliable component in biomanufacturing and analytical workflows.

Recombinant Transferrin

Recombinant transferrin is a 679-amino-acid glycoprotein, expressed in Pichia Pastoris. It regulates iron transport and storage, facilitating cell expansion and differentiation in stem cell cultures. This glycoprotein supports cryopreservation, cell banking, and diabetes treatment. Its precise control of iron homeostasis ensures optimal cell growth and vitality, making it critical for advanced cell culture systems.

Recombinant Trypsin (Standard and USP Grade)

Trypsin, a 223-amino-acid serine protease expressed in Pichia Pastoris, is available in standard and USP grades. It cleaves peptide bonds at lysine and arginine residues, enabling precise protein processing. Trypsin is used in insulin and vaccine manufacturing, cell dissociation, and protein isolation. Its well-defined α:β ratio ensures consistency in both research and industrial applications.

Recombinant Carboxypeptidase B

Carboxypeptidase B, a 307-amino-acid exoprotease, is expressed in Pichia Pastoris. It cleaves basic amino acids like lysine and arginine from the C-terminal of peptides. Widely used in insulin production and antibody quality control, this enzyme supports pharmaceutical ingredient manufacturing. Its robust activity enhances sequence-specific proteolysis, ensuring precision in biotechnological workflows.

Tech Talk: The Science Behind the Magic at Laurus Bio

Laurus Bio supports the cultured meat industry by providing AOF recombinant proteins and growth factors that eliminate the need for animal-derived serum and media components like Fetal Bovine Serum (FBS). Their food-grade versions of growth factors are tailored to meet the cost structure and large-scale requirements of cultured meat production, promoting sustainable and ethical meat alternatives.

Precision fermentation

Precision fermentation is a cutting-edge technology that harnesses the natural abilities of microbes to produce specific proteins and molecules. Laurus Bio engineers microorganisms such as Escherichia coli, Pichia pastoris, and Bacillus subtilis to act as “cell factories.” This process involves introducing genes that encode the desired protein into the microbial DNA. Once engineered, the microbes are grown in controlled environments where they express the target protein during fermentation. Precision fermentation ensures high yields, consistency, and a sustainable alternative to animal-derived products.

Microbial “Cell Factories”

The term “cell factories” refers to genetically engineered microbes that produce complex proteins, enzymes, and growth factors. Laurus Bio optimizes these microbes to maximize protein expression while ensuring product quality. For instance, they design microbial hosts to minimize byproduct formation and enhance the efficiency of protein synthesis.

Cell Culture Media Supplements

Their recombinant proteins serve as critical media supplements that enhance serum-free media formulations. By replacing animal-sourced supplements, Laurus Bio’s products ensure virus-free, consistent, and traceable components, improving the safety and efficacy of cell culture processes across various applications.

Biologics and Insulin Manufacturing

In the production of biologics and insulin, Laurus Bio’s AOF recombinant proteins and growth factors act as key process ingredients in both upstream and downstream processing. Their high-purity products provide consistency and traceability, essential for large-scale manufacturing of therapeutic proteins.

Vaccine Production

Laurus Bio’s recombinant proteins are integral to vaccine manufacturing, offering safer alternatives to animal-derived components. Their products contribute to virus-free vaccine production processes, ensuring higher safety and efficacy standards.

Stem Cell Culture and Regenerative Medicine

In regenerative medicine, their AOF recombinant proteins and growth factors are used as key process aids and critical components for specialized media in stem cell culture. These products provide safer, virus-free alternatives to animal-derived components, ensuring better lot-to-lot consistency, traceability, and efficacy in stem cell research and therapy.

Contract Development and Manufacturing Organization (CDMO) Services

Beyond their product offerings, Laurus Bio provides precision fermentation expertise as a CDMO service. They support clients from clone development and strain engineering to process development and large-scale commercial manufacturing. This comprehensive service aids novel protein companies and bio-manufacturers across healthcare, food, nutrition, personal care, and bio-based materials markets, facilitating the development and production of innovative biotechnological solutions.

Award-Winning Innovation: Laurus Bio’s Footprint in the Biotech Landscape

Laurus Bio’s commitment to quality and innovation has earned them recognition within the industry. Their parent company, Laurus Labs, has received several accolades, including the Economic Times ‘Corporate Excellence Award’ for Emerging Company of the Year 2021. Dr. Satyanarayana Chava, Founder & CEO of Laurus Labs, was honored as the Entrepreneur of the Year 2021 in the Healthcare and Life Sciences segment by Ernst & Young. (Laurus Labs)

In May 2024, Laurus Bio’s parent company, Laurus Labs, entered into a multi-product development and licensing partnership with Willow Biosciences, a biotechnology firm specializing in precision fermentation. This collaboration focuses on developing biobased processes for high-value active pharmaceutical ingredients (APIs), including corticosteroids. Willow leverages its AI-driven bioengineering platform to optimize enzyme, strain, and process engineering, while Laurus Labs oversees large-scale manufacturing, sales, and distribution.

Under the terms of the agreement, Willow Biosciences is set to receive $4 million in guaranteed research and development payments in the first year, with additional royalties based on worldwide sales upon commercialization. This collaboration enables Laurus Labs to adopt more sustainable and cost-effective methods for API production, reducing waste and improving efficiency. (Willow Bio)

The Price of Innovation: Funding Laurus Bio’s Big Ideas

The company recently secured a total equity funding of $18.9 million through a single funding round. This Series B round, finalized on December 6, 2024, was led by institutional investors Eight Roads Ventures and F-Prime Capital. The funding is expected to accelerate Laurus Bio’s expansion in fermentation-based manufacturing.

Prior to this, in November 2020, Laurus Labs acquired a 72.55% stake in Richcore Lifesciences for ₹246.67 crore, marking its entry into the biotechnology sector. Richcore was subsequently rebranded as Laurus Bio. (StartupTalky)

In terms of financial performance, Laurus Bio’s parent company, Laurus Labs, has reported robust revenue growth over the years. For the financial year 2022-23, the company recorded a revenue of ₹6,042 crore, marking a significant increase from ₹4,949.1 crore in FY 2021-22 and ₹4,835.9 crore in FY 2020-21.

Call It a Wrap: Laurus Bio and the Future of Sustainable Solutions

Laurus Bio is a pioneer in precision fermentation and recombinant technology. They create animal-origin-free proteins for biopharma, food, and personal care industries. Their innovations replace traditional, animal-derived components with sustainable and safe alternatives. With advanced strain engineering and microbial “cell factories,” they lead the way in ethical biomanufacturing solutions. Laurus Bio supports industries like cultured meat, regenerative medicine, and vaccines, making their processes sustainable and scalable.

Their work addresses key global challenges, including ethical sourcing and environmental sustainability. By eliminating animal-derived components, they improve safety and consistency. Laurus Bio’s technologies reduce environmental impact and promote innovative solutions across industries. Their collaborations and awards underscore their impact and leadership.

Are you inspired by Laurus Bio’s journey? Start working on your ideas today. Liked this article? Dive into our collection of inspiring stories on Venture Kites. Discover other game-changing companies and technologies shaping the future.

At a Glance with DORK Company

Dive In with Venture Kites

Lessons From Laurus Bio

Prioritize Sustainability

The Lesson & Why it Matters: Sustainability is not just a trend; it’s a necessity for long-term impact. Companies that adopt sustainable practices gain consumer trust and reduce environmental impact.

Implementation: Evaluate your processes for inefficiencies and environmental harm. Use renewable resources and minimize waste. Innovate with sustainability at the core.

How Laurus Bio Implements It: Laurus Bio eliminates animal-derived components by using precision fermentation, reducing environmental strain and promoting ethical practices.

Leverage Cutting-Edge Technology

The Lesson & Why it Matters: Innovative technology can transform industries. Staying ahead requires continuous adoption and improvement of new tools and techniques.

Implementation: Invest in research and development. Collaborate with tech experts to integrate advanced solutions into your operations.

How Laurus Bio Implements It: They use strain engineering and microbial cell factories to produce high-quality, animal-free proteins for diverse industries.

Adapt to Market Trends

The Lesson & Why it Matters: Markets evolve. Businesses must anticipate and adapt to stay relevant and competitive.

Implementation: Monitor industry trends and consumer demands. Be flexible and willing to innovate quickly.

How Laurus Bio Implements It: They address the growing demand for cultured meat and sustainable biomanufacturing solutions

Embrace Ethical Manufacturing

The Lesson & Why it Matters: Ethical practices create trust among consumers and stakeholders. Transparent and responsible operations align businesses with societal values.

Implementation: Analyze your supply chain and processes for ethical concerns. Adopt practices that minimize harm to animals, humans, and the environment.

How Laurus Bio Implements It: Laurus Bio completely avoids animal-derived inputs, promoting ethical alternatives in biomanufacturing.

Educate Your Market

The Lesson & Why it Matters: Innovative products often need education to gain acceptance. An informed market is more likely to adopt new solutions.

Implementation: Invest in awareness campaigns. Use simple, relatable messaging to explain your product’s value and impact.

How Laurus Bio Implements It: Laurus Bio educates stakeholders about the advantages of animal-free proteins, highlighting safety and sustainability.

Youtube Shorts

Author Details

Creative Head – Mrs. Shemi K Kandoth

Content By Dork Company

Art & Designs By Dork Company

Instagram Feed

X (Twitter) Feed

🚀 Inside Laurus Bio: The Biotech Disruptor 🧬🌱@LaurusLabs is redefining biomanufacturing with precision fermentation and recombinant technology. Let’s explore how they’re scaling biotech innovation and driving sustainability! 👇👇#Biotech #LaurusBio #Innovation

— Venture Kites (@VentureKites) February 11, 2025