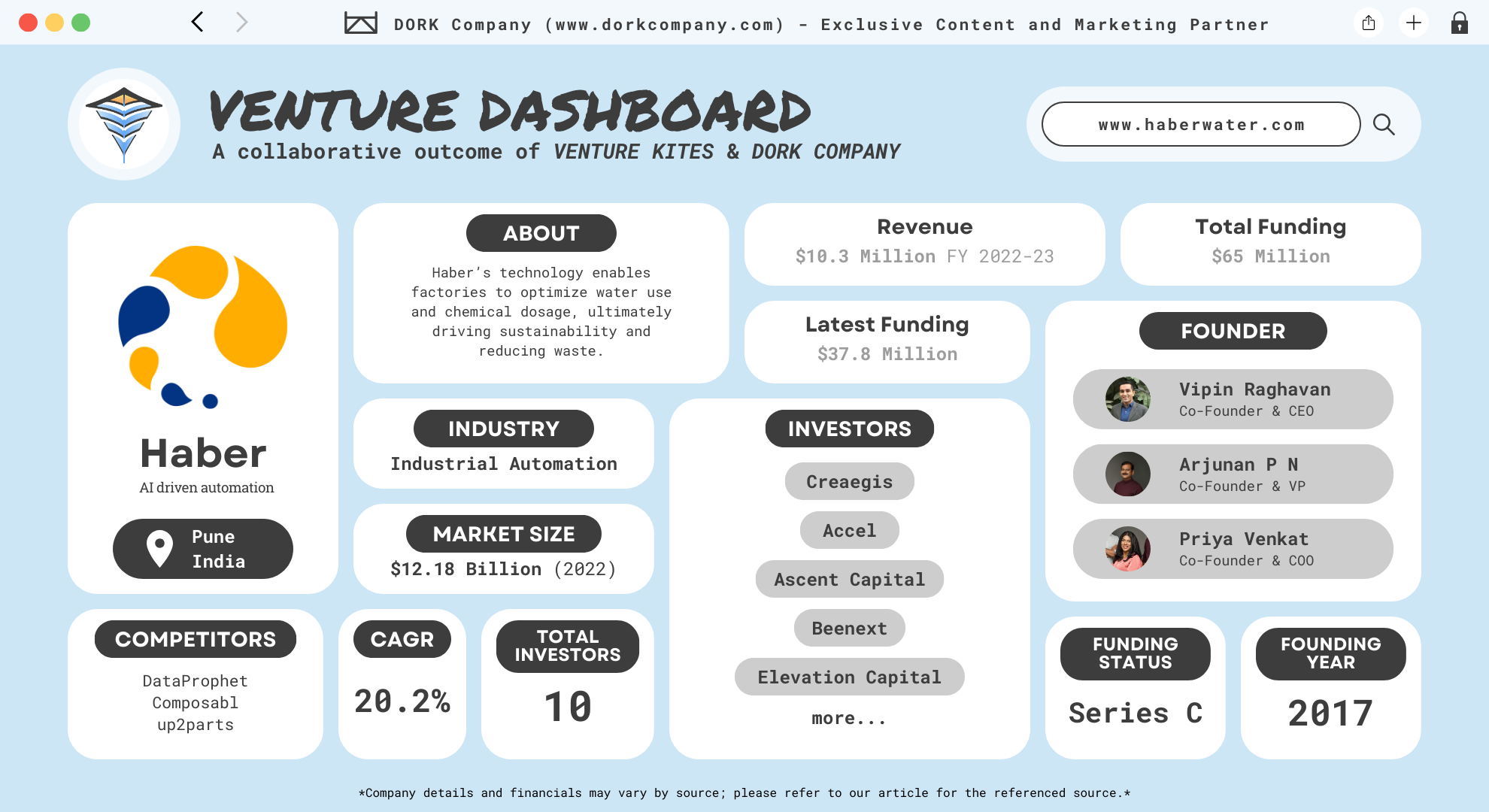

Haber Water : The AI Solution For Industry 7.0

Haber, a pioneering startup founded in 2017, leverages artificial intelligence (AI) to revolutionize water and chemical management in industrial settings. Founded by Vipin Raghavan, Arjunan PN, and Priya Venkat, the company is headquartered in Pune, India. The team recognized the vast inefficiencies in traditional water management and set out to build AI-driven automation solutions that streamline critical processes in industries such as food and beverage, pulp and paper, and institutional water management. (Haber)

Haber’s technology enables factories to optimize water use and chemical dosage, ultimately driving sustainability and reducing waste. Their flagship platform, eLIXA, automates sample collection, measurement, and analysis, translating data into actionable insights in real-time.

This innovation has reportedly saved clients over 50 billion liters of water and significantly reduced carbon emissions, showcasing the environmental impact of their technology. With a client list that includes prominent companies like ITC and Tata Steel, Haber’s solutions have gained widespread industry trust and validation. Haber continues to push the boundaries of AI in industrial automation, helping industries achieve substantial resource savings while enhancing operational efficiency.

The Rise of Haber: How Three Founders Saw a Tide of Opportunity

Haber Water was founded in 2017 by Vipin Raghavan, Priya Venkat, and Arjunan PN. Each founder brought extensive experience in technology and industry, which was pivotal in shaping Haber.

Vipin Raghavan

Vipin Raghavan, the CEO, holds a Bachelor of Technology from Model Engineering College and pursued further studies at Iowa State University. His career path spans several industries, where he held prominent roles in finance and management. Before co-founding Haber, he served as the Director of Finance at Nalco Water India (part of Ecolab), Zynga and United Health Group. (Vipin Raghavan)

Priya Venkat

Priya Venkat, the Chief Operating Officer, also came from a background at Nalco Water. Priya’s career spans various strategic and managerial roles, including pricing strategy and financial planning. Before Haber, Priya was Senior Manager at NALCO Water, where she handled strategy and pricing for the South Asia market. Additionally, she held finance and managerial positions at Zynga, ISGN Corporation, and Infosys. At Haber, she oversees operations and manage the company’s growth strategy. (Priya Venkat)

Arjunan PN

Arjunan PN, the Vice President of Technical, leads the technology side at Haber, where his deep expertise in AI and process automation has shaped the development of Haber’s flagship product, eLIXA. Arjunan has an extensive background in the field, with over 27 years of experience in projects, process management, and specialty chemicals, particularly in water treatment. Before joining Haber, Arjunan held a significant role as Technical Lead at NALCO. Arjunan holds a master’s degree in Pulp and Paper Technology from the Indian Institute of Technology, Roorkee, which supports his expertise in managing water treatment processes within industrial applications. (Arjunan PN)

Together, the trio identified a pressing gap in industrial water management: traditional methods were not only time-intensive but also resource-inefficient. Their combined experience across sectors and shared vision for using AI to optimize water and chemical usage drove them to create a company that could bridge this gap effectively.

The Perfect Storm: AI Meets Industrial Automation

The industrial automation market is rapidly growing, driven by advancements in AI technologies that enable industries to operate more efficiently and sustainably. In 2022, the AI in industrial automation market was valued at around USD 12.18 billion and is projected to reach USD 55.6 billion by 2030, expanding at a compound annual growth rate (CAGR) of 20.2%. (Future Data Stats)

This robust growth reflects an increasing reliance on AI for optimizing processes such as predictive maintenance, quality control, and supply chain management across diverse industries. AI integration in automation has transformed industries like manufacturing, automotive, and healthcare. Predictive maintenance is a major application, as AI algorithms analyze historical data to forecast equipment failures, significantly reducing downtime and maintenance costs.

Quality control has also improved, with AI-based systems capable of detecting defects with higher accuracy, enhancing product quality in sectors like electronics and automotive manufacturing. Regionally, North America leads the AI-driven automation market due to its advanced technological infrastructure, followed closely by Asia-Pacific, where countries like China and Japan invest heavily in smart manufacturing and AI applications. Europe also plays a substantial role, propelled by its emphasis on robotics and high automation density. (Fortune Business Insights)

Pouring Innovation into Every Drop: Haber’s Mission and Vision

Mission

Haber’s mission is to drive sustainability in industrial processes by optimizing water and chemical usage. They aim to reduce resource waste and environmental impact through AI-driven automation, making industrial operations more efficient and sustainable. (About Haber)

Vision

Haber envisions a future where AI and data-driven insights replace traditional, manual processes in industries. Their goal is to lead in sustainable solutions, empowering industries to manage water resources responsibly while enhancing profitability..

Problems They Solve

Haber addresses several challenges in industrial water management, such as water scarcity, inefficient chemical dosing, and high operational costs. Their solutions, like the eLIXA platform, automate sample collection, real-time monitoring, and chemical dosage adjustments, resulting in significant reductions in water and chemical waste. By optimizing these processes, Haber helps industries comply with environmental standards while lowering operating costs.

Business Model

Haber operates on a recurring revenue model that combines hardware installation, SaaS-based software billing, and chemical consumable charges. This structure allows clients to transition smoothly to automated processes, benefiting from predictable costs tied to production levels. The eLIXA platform, which powers most of Haber’s solutions, integrates with existing systems to provide actionable insights, requiring minimal customization. This scalability and flexibility enable quick deployment across different sectors, including pulp and paper, food and beverages, and institutional water management.

Tools of the Trade: Haber’s Arsenal of Water-Saving Solutions

Kaiznn

Kaiznn is an advanced deckle matching and production management solution designed to maximize efficiency by minimizing trim loss and enhancing order fulfillment. This intelligent platform enables pulp, paper, and packaging industries to manage complex production tasks seamlessly.

It features a Deckle Matching Solution that provides multiple optimized match combinations in seconds, Order Management for recording, prioritizing, and tracking orders in a centralized system, and Production Management for real-time monitoring of production and rewinding schedules. Additionally, Kaiznn supports detailed configuration of production facilities, allowing businesses to set up machine and rewinder specifications that meet their unique operational needs. This intuitive platform integrates easily with existing systems, minimizing the need for extensive training or setup and enabling companies to streamline complex production workflows, maximize resource utilization, and reduce operational costs. (Kaiznn)

Mt. Fuji

Mt. Fuji by Haber Water is an advanced production and process intelligence platform that streamlines operations across multiple production sites. This AI-powered platform provides a real-time overview of key performance indicators (KPIs). Key features of Mt. Fuji includes refined traceability for tracking production stages, standardized data collection for consistent and reliable insights, instant alerts for timely response to issues, and comprehensive data visibility across all sites.

The platform is structured around several key functionalities: Elevate Data, which ensures accurate, standardized data collection across systems; Visualize Insights, allowing operators to gain actionable insights and monitor trends; Enhance Operations through continuous process improvements informed by AI analysis; and Unleash AI, utilizing predictive analytics to anticipate and mitigate potential issues. (Mt. Fuji)

Haber Water Solutions

Haber Water Solutions offers an innovative, AI-driven water management system designed to enhance sustainability and optimize water use in industrial settings. Designed to maximize water efficiency, these solutions integrate real-time data analysis, which allows operators to monitor and control water usage precisely. Through predictive analytics and machine learning, the system assesses and adjusts water flow rates, pressure, and other critical variables, ensuring that water resources are used effectively while minimizing waste. (Haber Water)

It integrates seamlessly with existing infrastructure, delivering data-backed insights directly to operational teams. By constantly tracking water quality, contamination levels, and resource consumption, the system can quickly identify potential issues such as leaks, overuse, or contamination. Additionally, the solution’s advanced AI algorithms continually improve water management by learning from historical data, reducing the operational and environmental impact of water-intensive processes.

Haber Utilities Solutions

Haber Utilities Solutions is an AI-driven platform specifically designed to optimize cooling tower and boiler operations, enhancing asset integrity, and boosting plant efficiency. By automating adjustments in critical parameters such as water flow, temperature, and chemical dosing, Haber Utilities Solutions maintains system stability, reduces energy consumption, and minimizes resource waste.

Key technical functionalities include continuous tracking of parameters like water quality, pH, and scale formation in cooling towers, which helps prevent fouling and corrosion. In boiler operations, the system optimizes steam generation by balancing water usage and controlling heat, thus enhancing fuel efficiency. Advanced AI algorithms assess historical and real-time data to detect anomalies and provide predictive maintenance alerts, which help prevent system failures before they occur. (Haber Utilities)

Haber Process Solutions

Haber Process Solutions provides automated, AI-driven process optimization solutions that help industries make informed and accurate decisions to improve plant efficiency. The core functionalities of Haber Process Solutions include continuous monitoring and adjustment of key process parameters, such as temperature, pressure, flow rates, and chemical concentrations. By integrating machine learning algorithms, the platform can predict system requirements, automatically adjusting dosing and other variables to maintain optimal operating conditions. This results in reduced reliance on manual intervention and increased consistency in product quality. (Haber Process)

Pulp and Paper Packaging Solutions

Haber’s pulp and packaging solution, powered by the eLIXA® platform, offers extensive automation for chemical management and process optimization. (Pulp and packaging)

Key applications include:

- RDA (Retention and Drainage Aid): An automated chemical preparation system for fiber retention and chemical drainage, improving resource efficiency.

- MBC (Microbial Control): Controls organic load in the system with real-time monitoring and optimized dosing of antimicrobial agents.

- SLS (Solid-Liquid Separation): Uses AI-driven dosing for efficient separation, maximizing fiber recovery and contaminant removal from water.

- Brightness Control: Ensures consistent brightness in output through AI models that adjust chemical dosing based on real-time data.

- Scale Control: AI and machine learning algorithms monitor parameters like pH, temperature, and pressure, preventing scale formation which affects product quality and system flow.

- Defoamer Program: Controls foam formation, improving quality and reducing costs associated with excessive chemical use.

- Strength Aids & Surface Sizing: Critical for determining paper quality, these solutions provide real-time monitoring of chemical dosing to meet strength and water resistance specifications

The company also provides Food & Beverage solutions. The system uses AI to continuously monitor water quality and chemical levels, adjusting treatment processes in real-time to ensure optimal product quality and safety. (Food & Beverage)

For institutional facilities, such as hospitals, universities, and commercial complexes, Haber’s solution addresses common challenges like water scaling, high energy costs, and maintenance overhead. The system detects issues such as scale deposits on equipment, which can lead to inefficiencies and failures. This approach improves asset longevity and reduces operating costs, supporting sustainable practices across large facilities. (Institutioinal solutions)

The Ripple Effect of Haber’s Journey : How Haber Fuels Its Growth

Haber has established themselves as a trusted partner among top industry leaders, including ITC, Tata Steel, and Emami. They have significantly impacted the industrial water management sector with their AI-driven platform, eLIXA®. It has saved over 30 billion liters of water and reduced chemical usage by up to 20%, supporting industries in minimizing environmental footprints and lowering operational costs. This solution has also achieved substantial energy savings, recorded at around 79,045 MW, and eliminated over 75,000 tons of carbon emissions, illustrating their contribution to environmental goals and carbon reduction initiatives globally. (Haber Impact)

Haber Water, since its founding in 2017, has raised substantial capital to fuel its expansion in industrial automation and sustainable water management. They have raised a total of $65 million in equity funding across four rounds.

1. Seed Round – June 29, 2017

In 2017, Haber Water secured its first round of funding through a seed round, raising $1.2 million at a valuation of $5.2 million. This funding came from institutional investor Elevation Capital. This initial investment supported the development of Haber’s core technology, helping the company establish its first client relationships and prove its solution’s viability. At this stage, Haber reported revenue of $581,000.

2. Series A – April 23, 2019

Haber raised $6 million in a Series A round with a valuation of $19 million. The funding round included investments from Accel, Beenext, and Elevation Capital, with corporate backing from IndigoEdge. This influx of capital enabled Haber to expand its technology capabilities and scale operations, targeting larger industrial clients. By 2019, the company’s revenue had reached $1.2 million.

3. Series B – August 13, 2021

In 2021, Haber secured $20 million in a Series B round, which brought the company’s valuation to $80.7 million. Leading investors included Ascent Capital, Beenext, Elevation Capital, and Accel, with additional support from corporate investor IndigoEdge and angel investors such as Mukul Chawla, Akash Gupta, and Samay Kohli. This funding allowed Haber to enhance its product offerings and boost revenue, which had grown to $4.2 million by this time.

4. Series C – October 10, 2024

In its latest funding round, Haber raised $37.8 million in a Series C round. Creaegis, Accel, and Beenext led this round.

Revenue

Haber Water has also shown impressive revenue. In its initial fiscal year, Haber Water generated revenue of $24.7K, a modest start for the company as it began deploying its AI-driven solutions in industrial settings. In the latest fiscal year, FY 2022-23, their revenue surged to $10.3 million, nearly doubling from the previous year of $6.1 million. Their recent reported revenue indicates substantial market adoption and the success of Haber’s scalable automation solutions.

Wrapping Up : Catch the Wave of Innovation with Haber”

Haber Water has carved a niche in industrial automation by transforming water and chemical management with its AI-powered eLIXA® platform. The company optimizes water and chemical usage in industries like pulp and paper, food and beverages, and institutional facilities, providing real-time data analytics, automated dosing, and environmental impact reduction. Haber’s approach not only saves resources but also helps industries reduce costs and comply with sustainability goals.

Haber’s solutions have had a great impact on its clients’ operations. For instance, eLIXA® has reportedly saved clients over 24 million cubic meters of water and reduced emissions by over 75,000 tons.

Haber Water’s journey shows that with the right mix of innovation, strategic focus, and commitment to sustainability, companies can drive meaningful change. If you’re working on an idea, let Haber’s story inspire you to pursue it further.

For more deep dives into pioneering companies and innovative solutions, explore other articles on Venture Kites. Here, you’ll find insights into how startups are shaping the future across industries and markets.

At a Glance with DORK Company

Dive In with Venture Kites

Lessons From Haber

Gain Market Trust with Transparent Metrics

The Lesson & Why it Matters

Transparent reporting on performance metrics builds credibility. Clients gain trust when companies provide clear, quantitative results.

Implementation

Share performance reports with clients regularly, including data on product efficiency, savings, and improvements.

How Haber Implements It

Haber regularly shares success metrics, such as specific reductions in water and chemical use, building trust with high-profile clients like Tata Steel and Emami

Invest in Seamless Integrations

The Lesson & Why it Matters

Products that integrate easily into existing workflows have a higher adoption rate, as they lower operational disruption and training costs.

Implementation

Ensure your product integrates with widely used systems. Design flexible features to connect with various industrial platforms and dashboards.

How Haber Implements It

Haber’s platform integrates with clients’ existing systems, including SCADA, ensuring minimal disruption to ongoing operations

Prioritize Sustainable Business Models

The Lesson & Why it Matters

A sustainable business model considers both environmental impact and long-term financial viability. Clients prefer solutions that align with these dual goals.

Implementation

Develop products that generate value beyond short-term gains, focusing on sustainability to attract clients committed to environmental goals.

How Haber Implements It

Haber’s recurring revenue model, which includes monitoring and adaptive chemical dosing, is designed for sustainable impact and financial predictability

Engage Clients in Product Development

The Lesson & Why it Matters

Customer-centric development ensures products meet real-world needs. Engaging clients in product design boosts relevancy and user adoption.

Implementation

Collaborate with clients during the development process. Regularly gather feedback to ensure your product is aligned with operational realities.

How Haber Implements It

Haber works closely with clients across sectors, adjusting its solutions based on real-world feedback and industry demands

Scale Smartly with Targeted Expansion

The Lesson & Why it Matters

Expanding into new markets should be targeted and strategic. This focused approach allows companies to scale efficiently.

Implementation

Identify industries or regions where your product’s value proposition is most relevant. Develop a structured plan for expansion.

How Haber Implements It

Haber has expanded from India to explore international markets like Indonesia, strategically targeting areas with large paper industries

YouTube Shorts

Author Details

Creative Head – Mrs. Shemi K Kandoth

Content By Dork Company

Art By Dork Company

Instagram Feed

X (Twitter) Feed

🚀 @haber_tech is transforming industrial automation with AI-driven water and chemical management solutions! 🌊⚙️

— Venture Kites (@VentureKites) November 12, 2024

Let’s dive into how they’re helping industries save resources and operate more sustainably 👇👇#IndustrialAutomation #AI #Sustainability