Ambercycle’s Style Revolution: Trash, Meet Your Makeover!

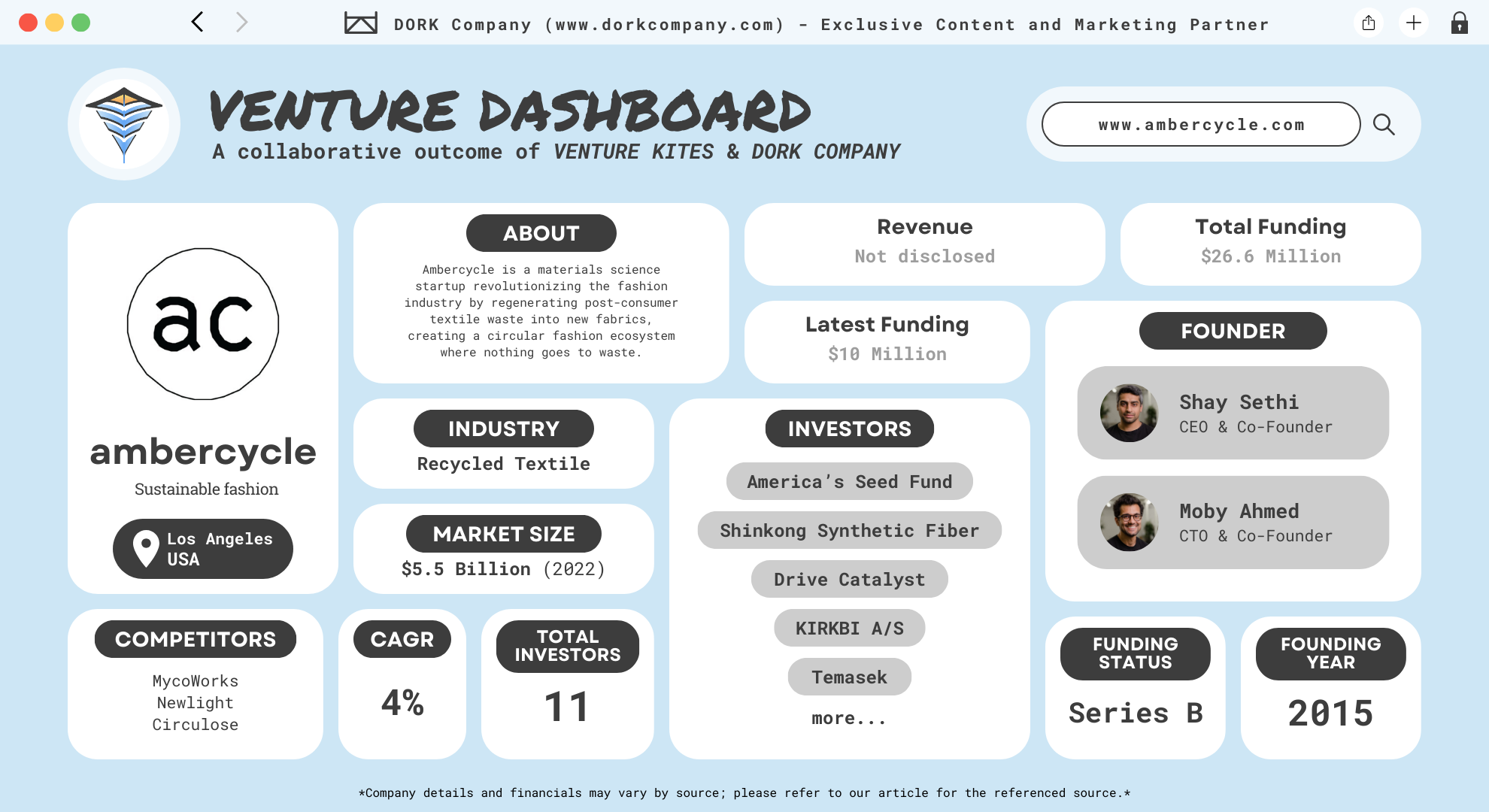

We’ve all heard the phrase “reduce, reuse, recycle,” but what if I told you there’s a company taking that to the next level—literally regenerating old clothes into new ones? Say hello to Ambercycle, a materials science startup that’s reforming the fashion industry. Founded in 2015 by Shay Sethi and Moby Ahmed, Ambercycle was born from the desire to solve one of fashion’s biggest problems: textile waste. Based in Los Angeles, Ambercycle is on a mission to build a circular fashion ecosystem where nothing goes to waste. (Ambercycle)

The fashion industry is one of the largest polluters in the world, with billions of garments ending up in landfills every year. Ambercycle tackles this problem head-on with its proprietary process, Ambercycling™, which separates and purifies post-consumer textile waste at the molecular level. Their breakthrough product, Cycora®, is made from this waste, giving discarded clothes a new lease on life.

The company’s journey started in California, where both founders attended UC Davis. Originally working with genetically engineered microbes to recycle plastic waste, they later switched to a more efficient chemical process. Today, Ambercycle has garnered millions in funding and is collaborating with big names in fashion like H&M to push forward the concept of circularity in clothing.

Two Guys, One Mission: Turning Old Clothes into New Dreams

Imagine turning a dorm room idea into a company that’s changing the world. That’s exactly what Shay Sethi and Moby Ahmed did when they co-founded Ambercycle. The two were roommates at UC Davis, and their late-night discussions about sustainability led them to develop a technology that could tackle one of fashion’s biggest problems—textile waste. (Shay Sethi)

Both founders graduated from UC Davis in 2015 with degrees in science. Shay Sethi holds a Bachelor’s in Biochemistry and Molecular Biology, while Moby Ahmed earned his degree in Genetics and Genomics. Their academic background gave them the technical foundation to experiment with recycling textiles at a molecular level. While still students, they initially started working on microbial methods to recycle plastics but quickly pivoted to using a more efficient chemical process after realizing the limitations of microbes. (Moby Ahmed)

What started as a small project has since grown into Ambercycle, a materials science company that uses its proprietary process, Ambercycling™, to convert post-consumer textile waste into new fabrics. The company was officially founded in 2015 in San Francisco but later moved to Los Angeles, where it’s currently headquartered.

The recycled textile market: Recycling Never Looked This Good!

The recycled textile market is spinning a new thread in the fashion industry. With growing environmental concerns, the market is poised for steady growth over the next decade. In 2022, the global recycled textile market was valued at approximately $5.5 billion. Experts predict it will reach $8.5 billion by 2032, growing at a CAGR of 4% (Global Market Insights Inc.)

The market’s growth is driven by rising awareness of the negative environmental impacts of textile waste. Roughly 75% of textile waste is landfilled, while only 25% is recycled, indicating a significant need for better waste management strategies. The demand for sustainable fabrics has pushed industries to adopt eco-friendly practices, with the apparel and home furnishings sectors leading the way.

One of the most exciting trends is the shift toward recycled polyester, a fabric made from post-consumer plastic bottles and textile waste. This material is becoming increasingly popular in the production of sportswear and fast fashion. By 2032, recycled polyester is expected to dominate the market, reaching $4 billion.

Key players, such as Lenzing AG, Patagonia and Unifi, are at the forefront of this transformation. They are using advanced mechanical and chemical recycling processes to convert textile waste into new materials. This market is expected to see the strongest growth in Asia-Pacific, particularly in India and China, where governments are implementing textile recycling initiatives. Despite the challenges of high capital costs and limited recycling infrastructure in some regions, consumer demand for eco-friendly products continues to rise, fueling the market’s future growth. (Expert Market Research)

About Ambercycle : Giving Old Fabrics a Fresh, Sustainable Future

Ambercycle aims to revolutionize how we think about materials, ensuring that waste is eliminated and resources are continuously reused. Their vision is to create a world where new materials are no longer derived from finite, extractive sources but from above-ground goods, focusing on circularity in high-growth industries like fashion and automotive.

Mission

Ambercycle’s mission is simple but impactful: to build a circular fashion ecosystem where materials can flow in and out of use without generating waste. They achieve this through their molecular regeneration technology, which breaks down post-consumer textile waste into new, high-quality fabrics like Cycora®, allowing brands to produce sustainable fashion.

Problems They Solve

Ambercycle tackles one of fashion’s biggest problems—textile waste. Over 120 billion garments are discarded annually, much of it ending up in landfills. Ambercycle’s breakthrough process, Ambercycling™, separates and purifies old textiles at the molecular level, regenerating them into reusable materials. This approach reduces reliance on virgin resources, minimizes waste, and decarbonizes industries by lowering their environmental impact.

Business Model

The company operates with a B2B business model, collaborating with fashion brands to supply sustainable materials. By converting textile waste into products like Cycora®, Ambercycle enables brands to integrate recycled polyester into their collections without sacrificing quality or style. Their partnerships with industry giants like H&M and Zalando showcase how Ambercycle helps companies achieve their sustainability goals.

Cycora®: The Fabric of Our (Sustainable) Lives

Products

- Cycora® Polyester: Ambercycle is redefining the future of textiles with its flagship product, Cycora®. Cycora® is a regenerated polyester made from end-of-life textiles, offering a sustainable alternative to conventional polyester. What sets Cycora® apart is its ability to deliver virgin-grade quality while reducing environmental impact. This high-performance material is designed to meet the needs of fashion brands seeking circular solutions, helping them reduce their carbon footprint and dependency on virgin materials

- Regenerated Fabrics: Ambercycle’s molecular recycling process ensures that their fabrics can be regenerated multiple times, overcoming the limitations of traditional mechanical recycling, where quality degrades after each cycle.

Services

- Textile-to-Textile Recycling: Ambercycle partners with brands to integrate their Cycora® fabric into collections, helping these brands transition to circular production models. Collaborations with H&M, Gap Inc., and Reformation showcase their capability to deliver on large-scale projects.

- Sustainability Consulting: Ambercycle helps companies embed circularity in their supply chains by offering regenerated materials and expertise in reducing the carbon footprint of their textile sourcing.

Features

- Molecular Regeneration: Unlike conventional recycling, Ambercycle’s process purifies textiles at the molecular level, removing impurities and dyes, and regenerates the material into new fibers without compromising on quality.

- Circular Ecosystem: Cycora® fabrics are designed to be recycled again, promoting true circularity in fashion. Garments made from Cycora® can be recycled repeatedly, further minimizing waste.

Ambercycle’s innovative approach to circular textiles is revolutionizing fashion’s relationship with materials, setting new standards for sustainability.

Regenerate, Don’t Hesitate: The Tech Behind Ambercycle’s Fabric

Ambercycle’s technology is changing the way we think about recycling textiles. Using a process called molecular regeneration, they break down old clothes at the molecular level and rebuild them into brand-new fibers. (Technology)

The molecular regeneration process works in several stages. First, textiles that would otherwise end up in landfills are collected. Buttons, zippers, and other non-textile components are removed. Then, the fabrics are shredded and broken down into their molecular building blocks. These molecules are purified, removing dyes and other contaminants, and reconstituted into high-quality polyester fibers.

Unlike traditional recycling methods, which degrade material quality over time, molecular regeneration preserves the durability of the fiber. This means that Cycora® can be reused multiple times without losing its strength or versatility. The material behaves just like virgin polyester, making it a seamless replacement in existing supply chains for fashion brands.

Powerhouse Collaborations : Ambercycle’s Impact on the Circular Fashion Revolution

Ambercycle is building an impressive network of global partnerships to drive the circularity movement in fashion. One of their most notable partnerships is with Reformation, a leading sustainable fashion brand. Together, they’ve launched collections featuring Cycora® material, marking a significant step towards closed-loop garments in the fashion industry. (Reformation)

Ambercycle has also partnered with Hyosung TNC, a South Korean leader in sustainable textiles, to scale up the production of Cycora®. This partnership taps into Hyosung’s decades of experience in producing high-quality fibers, bringing Ambercycle’s circular polyester into global supply chains. (Hyosung TNC)

Their collaboration extends beyond fashion into the outdoor gear industry with NEMO Equipment, where they’re working to create fully recyclable products. NEMO’s Endless Promise™ program is using Cycora® to ensure products like sleeping bags are recycled at the end of their life cycle. (NEMO)

Another notable collaboration is with MAS Holdings, a global apparel manufacturer. This partnership centers on a three-year agreement that allows MAS to integrate cycora® into its supply chain, advancing its sustainability goals. MAS aims to generate 50% of its revenue from sustainable products by 2025, with cycora® playing a key role. (MAS Holdings)

Ambercycle has also partnered with Shinkong Synthetic Fibers, a leading yarn producer. Together, they are scaling the production of high-performance yarns made from cycora. Additionally, they have a strategic agreement with Inditex, the parent company of Zara which has committed to buying cycora® for over €70 million, which will significantly expand Ambercycle’s production and bring circular materials to a broader market. (Inditex)

Ambercycle’s Financial Journey : Cash Flows & Circular Fashion’s Growth

Ambercycle has been attracting major investors in its mission to revolutionize textile recycling. The company has raised a total of $26.6 million in funding across several rounds, with support from prominent backers like H&M Co, Kirkbi, Temasek, and Zalando. (Tracxn)

In July 2017, Ambercycle received its first significant boost with a $225K grant from America’s Seed Fund, marking the beginning of its innovation journey. Just over a year later, in September 2018, the company secured another $750K grant from the same fund, further enabling research and development.

The company’s first major funding round came in January 2022, when it raised $21.6M in Series A funding. This round was led by KIRKBI A/S, Temasek, and Bestseller’s Invest FWD, with corporate participation from Zalando and H&M CO. Legal facilitation was handled by DLA Piper. This investment helped Ambercycle build its circularity ecosystem, expanding production of its innovative material, cycora®, and scaling the business.

In November 2023, Ambercycle raised $5M in Series B funding, led by Drive Catalyst. And most recently, in August 2024, the company secured $10M in conventional debt from Shinkong Synthetic Fiber.

The Future’s Sew Bright: Stitching Together a Circular Fashion World

Ambercycle is at the forefront of a sustainable revolution in the fashion industry. Their unique molecular regeneration technology, breaks down old, discarded textiles and regenerates them into new high-performance polyester, called cycora®. This process allows Ambercycle to address two significant challenges: reducing textile waste and decreasing the reliance on virgin polyester, which is made from non-renewable fossil fuels.

Ambercycle collects end-of-life textiles—clothes that would otherwise end up in landfills—and uses a proprietary chemical process to purify and regenerate them into new fibers. This not only diverts waste from landfills but also reduces carbon emissions and water usage compared to traditional polyester production. Ambercycle’s cycora® material maintains the same durability and performance as virgin polyester, making it an ideal sustainable alternative.

Through partnerships with major fashion brands like H&M, Zara, and Reformation, Ambercycle is helping to integrate circular materials into the global supply chain. Do you have an idea that could change an industry? Now’s the time to start working on it. For more inspiring stories of innovation, be sure to check out other articles on Venture Kites.

At a Glance with DORK Company

Dive In with Venture Kites

Lessons From Ambercycle

Redefine Waste as a Resource

The Lesson & Why it matters: Waste isn’t just disposable—it’s a valuable resource. This shift reduces environmental impact and creates a more sustainable world.

Implementation: Treat waste as a starting point for new materials. Invest in technologies that regenerate discarded resources.

How Ambercycle implements it: Ambercycle uses molecular regeneration to convert post-consumer textile waste into high-quality materials, reducing reliance on virgin resources

Scale Through Strategic Partnerships

The Lesson & Why it matters: Collaborating with larger companies can help scale innovative solutions more rapidly.

Implementation: Forge partnerships with industry leaders to access resources and markets.

How Ambercycle implements it: Ambercycle collaborates with Hyosung TNC and MAS Holdings to integrate cycora® into global supply chains, speeding up circular material adoption

Use Technology to Drive Decarbonization

The Lesson & Why it matters: Cutting emissions is critical for industries to meet climate targets. Technology plays a key role in decarbonization.

Implementation: Invest in low-carbon technologies that reduce the environmental footprint of your products.

How Ambercycle implements it: Ambercycle’s molecular regeneration technology reduces CO2 emissions by nearly 50% compared to virgin polyester production

Adapt Your Product for Multiple Industries

The Lesson & Why it matters: Expanding into new markets boosts resilience and growth opportunities.

Implementation: Develop versatile products that serve multiple industries and applications.

How Ambercycle implements it: While primarily targeting fashion, Ambercycle is also entering the automotive and electronics markets with cycora

Create a Circular Supply Chain

The Lesson & Why it matters: Circular supply chains cut waste and reduce costs by continually reusing materials.

Implementation: Build infrastructure that supports recycling and regeneration within your supply chain.

How Ambercycle implements it: Ambercycle’s circular model ensures that discarded textiles are processed and returned to the supply chain as high-quality materials

Youtube Shorts

Author Details

Creative Head – Mrs. Shemi K Kandoth

Content By Dork Company

Art By Dork Company

Instagram Feed

X (Twitter) Feed

♻️ Meet @ambercycle_ – the startup turning textile waste into new fashion!

— Venture Kites (@VentureKites) November 2, 2024

Founded by Shay Sethi & Moby Ahmed, Ambercycle's Cycora® fabric is a high-quality recycled material, helping brands like H&M & Zara go circular. 🌍👗#SustainableFashion #CircularEconomy